UHMWPE(Ultra High Molecular Weight Polyethylene Ropes) float in water making them significantly safer, their low stretch properties provide greater sensitivity and their low elongation combined with their low weight makes their handling easy and the manoeuvring of vessels extremely accurate especially in distress & critical times. Ultra High Molecular Weight Polyethylene (UHMWPE) ropes are 7-9 times stronger than steel (by weight) and 3 times stronger than Polyester of equal weight.

BLUEWIN

- Who We Are

- What We Supply

- Gallery

- Support

Copyright(C)Bluewin. All right reserved

- Search

-

- Products List

-

-

- Filter

Search results for 38

Dewatering Equipment

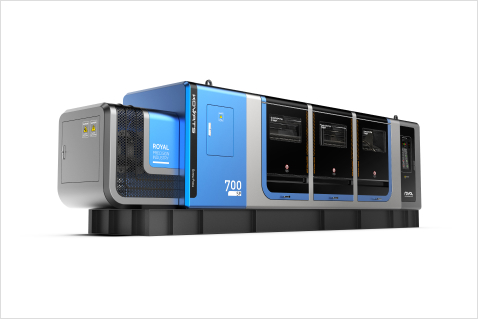

Royal-Decanter

This is the section that displays the description for the Royal Decanter

- FILFTER PRESS

Dewatering Equipment

Royal-Screw Press

The Royal Screw Press achieves very high efficiency with a low power consumption due to the low-speed operation. The power range is from 0.75 kW to a maximum of 5.5 kW with flow rates up to 200 GPM while producing 25%+T.S.cake

- SCREW PRESS

Dewatering Equipment

Filter Press Over Head Type

OFP(OverHead Filter Press) is to filter and dewater sludge from waste water created from various plants and houses. Suitable for waste-water processing plants, it can eliminate up to 50% of sludge by high pressure dewatering and drying. OFP(OverHead Filter Press) has a suitable structure for high pressure dewatering and its life is extended with optimal materials selected through structure analysis. OFP(OverHead Filter Press) the only high pressure sludge dewatering machine in Korea of which slu

- FILFTER PRESS

Dewatering Equipment

3-Phase Centrifugal Separator

Low speed centrifugal solid–liquid separating system is the one that controls the centrifugal force depending on the concentration and sludge dehydration rate, which controls the speed depending on the inflowing concentration of the matters, and also is a centrifugation system that separates the solid–liquid property of matters forcibly. Typical perforation type centrifugal solid–liquid separator has the maintenance problems because of the concentration of waste water (food and piggery effluent)

- CENTRIFUGE

Dewatering Equipment

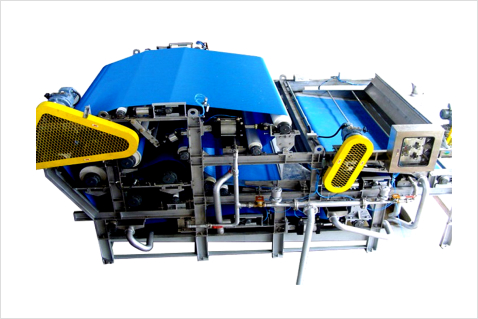

Dewatering Beltpress

AKI Beltpress is providing assembled with Pre-section+ 6~12 stage Roller Main Section+ After Section Component parts of Pre-Section, Drum Screen, Auto-Feeder, Belt Thickener + Dynamic Work Frame.

- Patent No. 10-2063960

- Registration No. 40-1646207

- BELT PRESS

Dewatering Equipment

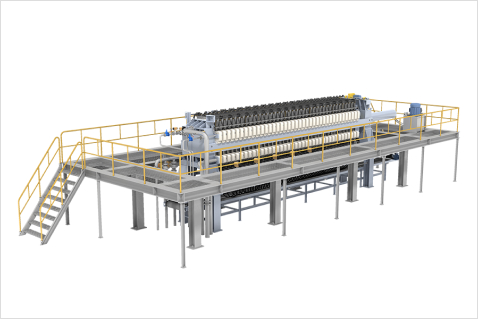

Vacuum Belt Filter

Vacuum Belt Filter is to filter and dewater sludge generated during desulfurizing and chemical processes and can be applied to various facilities and processes including power plants. Slurry coming from settlement and distribution facilities is spread over the filter top. And then it is vacuum-dewatered for final disposal. Compared to gypsum, the disposed slurry has 15~20wt% of water content and its thickness can be reduced to 30~70mm. For unmanned operation, sensors and transmitters are install

- BELT PRESS

Dewatering Equipment

Slow Drum type Thickener

The low speed drum thickener is the instrument which rotates the instrument with the way that it supplies the floc (Floc) which reacts the medicine at the sludge with the machinery sludge thickener and is cohered within drum and outside and concentrates at a low speed and transfers the sludge the concentration.

- SCREW PRESS

Dewatering Equipment

Electro Osmosis Dehydrator

The Electro Osmosis Dehydrator (ELODE, pronounced E-Load) further dewaters cake produced by mechanical dewatering equipment (eg. belt press, screw press, centrifuge). ELODE typically reduces cake weight by 50% or more in just 3 minutes. It consumes 300 kWh to remove 1 ton of water, using only electricity - no heat, chemicals, or mechanical force. Rather than using heat to boil water to steam like conventional thermal dryers, ELODE uses electrical polarity differences between solids and water

- CENTRIFUGE

Dewatering Equipment

Evaporative Dryer

The Evaporative Dryer (EVD) further dries cake produced by either ELODE or mechanical dewatering equipment (eg. belt press, screw press, centrifuge). This low temperature belt dryer processes cake at 10%DS+, drying it up to 90%DS+ to achieve Class A biosolids with a low operating temperature (≤85˚C). The EVD uses heat pumps in a closed loop, convection process to maximize heat recovery and minimize energy waste, consuming 400 kWh to remove 1 ton of water.

- CENTRIFUGE

Dewatering Equipment

Solid-Liquid Separator

The centrifuge corresponds to the particles separation and dehydration required as the various kind and many forms in the overall industrial field according to the characteristic of the workpiece selectively. With the consecutively control operation, continuous process for input-sedimentation -dehydration-exhaustion transfer and etc. is performed from xx ㎛ to xx mm size. It's kinds of centrifuge which concentration of the workpiece is 0~50% and object can be extensive and which can large scale t

- CENTRIFUGE

Dewatering Equipment

Dewatering Decanter Centrifuges

DEWATERING DECANTER use centrifugal force which is applied by the thousands times of the gravity inside the rotation Bowl, solid & moisture is broken down and the solid is the ejected by low moisture Cake with the shear and compression force effect. By using of specific gravity and centrifugal force, treat as dried sludge. by dewatering of fluid which is flowed in the outside drum (Bowl) within the fast time,

- CENTRIFUGE

Dewatering Equipment

Thickening Decanter Centrifuges

In the auto control mode, although the concentration of the input sludge changes from time to time, THICKENING DECANTER CENTRIFUGE control automatically for different speed value, ejected flude is constant concentrate and possible to continuous treatment with setted density value. The residual sludge of the low concentration is ejected into the high enrichment and even though the coagulant is not used, the solid (SS) can be removed over the recovery rate 90%.

- CENTRIFUGE

Dewatering Equipment

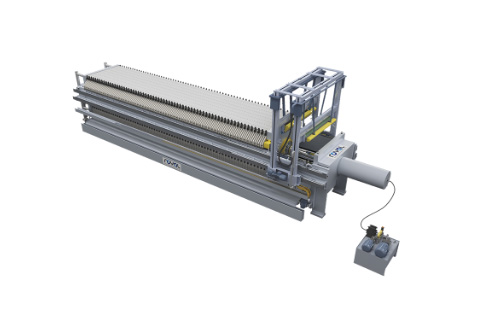

Filter Press Moving Cloth Type

MFP(Moving Cloth Filter Press) is to filter and dewater sludge from waste water created from various plants. As the filter cake moves up and down to remove cakes, unmanned automatic operation is possible. Suitable for waste-water processing plants, it can eliminate up to 50% of sludge by high pressure dewatering and drying. MFP(Moving Cloth Filter Press) has a suitable structure for high pressure dewatering and its life is extended with optimal materials selected through structure analysis. MFP(

- BELT PRESS

Dewatering Equipment

Filter Press Side Bar Type

SFP(Sidebar Filter Press) is to filter and dewater sludge from waste water created from various plants and houses. Suitable for waste-water processing plants, it can eliminate up to 50% of sludge by high pressure dewatering and drying. SFP(Sidebar Filter Press) has a suitable structure for high pressure dewatering and its life is extended with optimal materials selected through structure analysis. SFP(Sidebar Filter Press) the only high pressure sludge dewatering machine in Korea of which slurry

- BELT PRESS

ENGLISH

ENGLISH